Technologies

Give us the task – we'll provide you with the answer

Textile finishing

What colour would you like? Our textile chemistry know-how allows us to dye our products in almost any shade imaginable, with the dye withstanding up to 1,000 boil washes. Do you have any special requirements? Our products and finishes can be tailored as you need them: boil-wash resistant, weldable, antimicrobial, soft and skin-friendly (certified according to OEKO-TEX®), electrically conductive and antistatic as well as flame retardant for the special requirements of the automotive and aircraft industries.

Adhesives & adhesive coatings

In case our fastening systems need to be bonded, our expertise ensures a secure hold. We can adapt the formulations of adhesives or develop them ourselves and apply a wide variety of adhesive types in any grammage as well as in large-scale production. Depending on the surface, further processing or application, we use one- and two-component systems as well as pressure-sensitive adhesive systems. Self-adhesive fasteners are available with an easily removable overhanging cover film, certain adhesive-coated fasteners are also available without cover film.

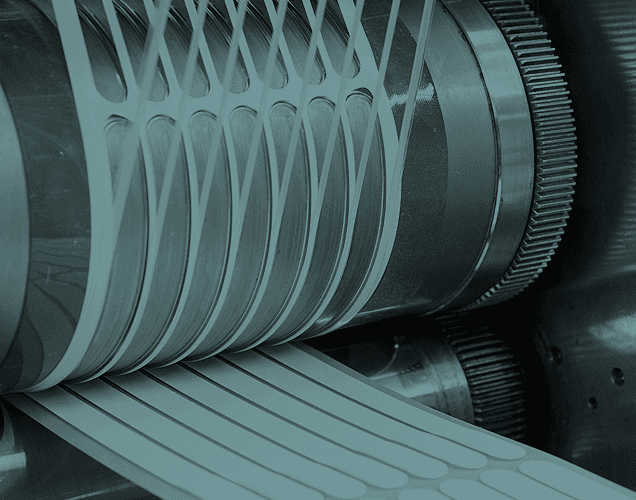

Surface technology

Only through the correct connection to the respective surface can the selected closure system develop its full performance. To achieve this, we use various surface treatment methods: atmospheric pressure and low-pressure plasma, corona treatment and gas phase fluorination. We also offer special coatings for improved bonding.

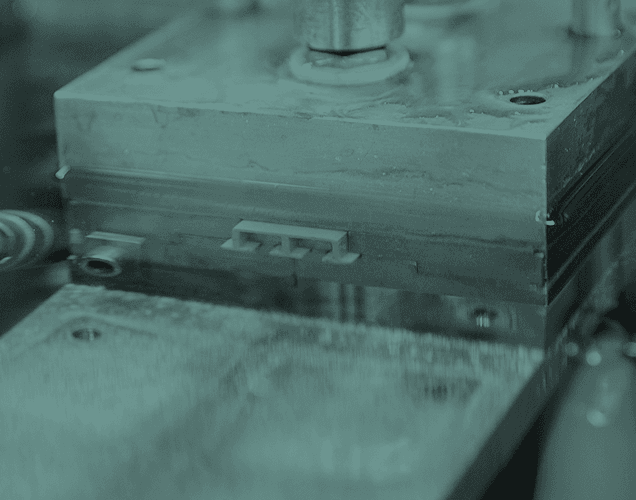

Profile extrusion & injection moulding

Profiled in extrusion technology: We produce profile shapes from all common plastics on our own profile extrusion lines according to your requirements. During the extrusion process, we can apply fastener systems inline using our expertise in surface and adhesive technology. Our application and customer-specific injection moulded parts can also be fully automatically fitted with fasteners. This enables us to produce large quantities of fastener systems in consistently high quality in the shortest possible time.

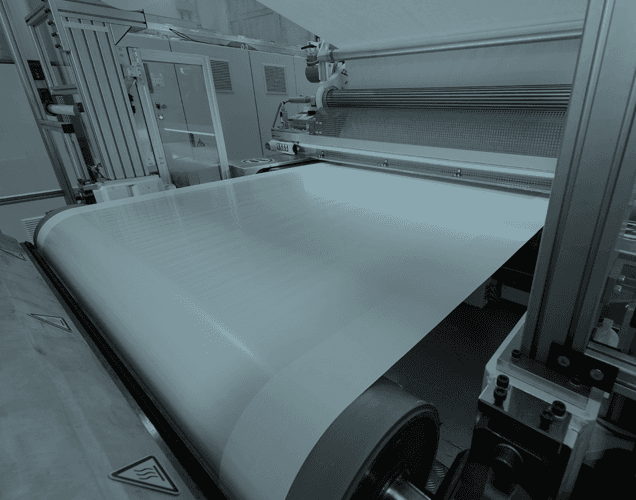

Converting

Extras or special requirements? Just tell us what you want. There are no limits to our converting options: whether punching, cutting, sectioning, laminating or coating, in large and small series. We can supply geometric parts on carriers, as individual parts or perforated. For cut goods we offer you different spooling and winding options. And our basic products are available in a variety of combinations in back-to-back processing.

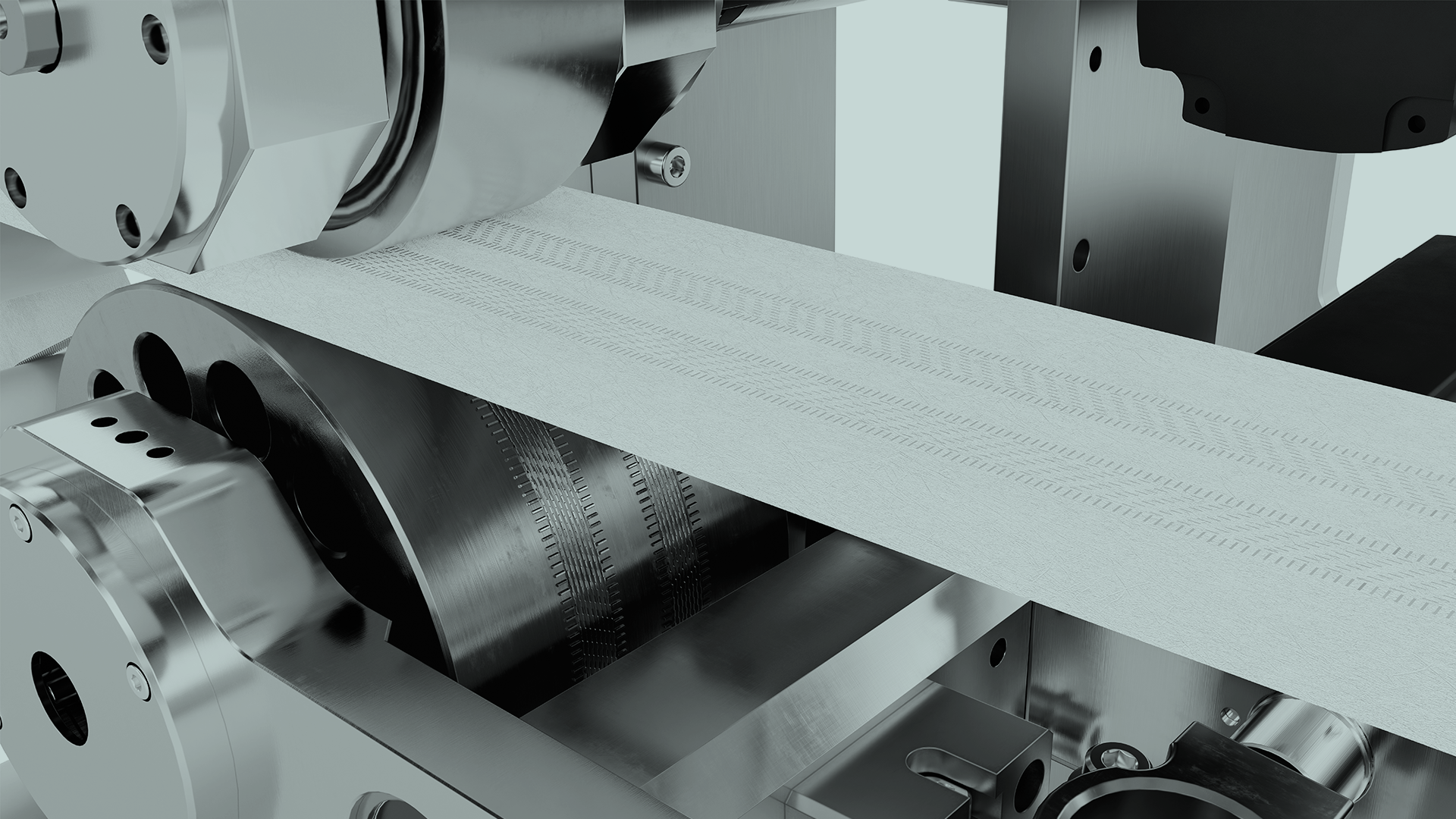

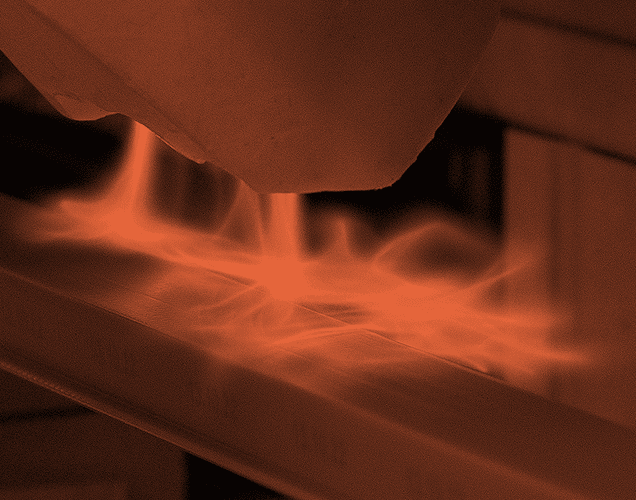

In-line welding

Our new in-line welding technology makes it possible to produce a closure system without adhesives or glues. Thanks to this innovation, a particularly soft diaper closure is achieved, which also reduces production costs and simplifies processing. This sustainable solution is an efficient alternative to conventional glueing methods and optimises both wearing comfort and cost-efficiency. Directly integrating proven, trusted ultrasonic technology into your production line delivers multiple benefits for your company, from lower costs to greater efficiency in production.