Binder & MS Ultrasonic: collaborating for customer success and sustainability

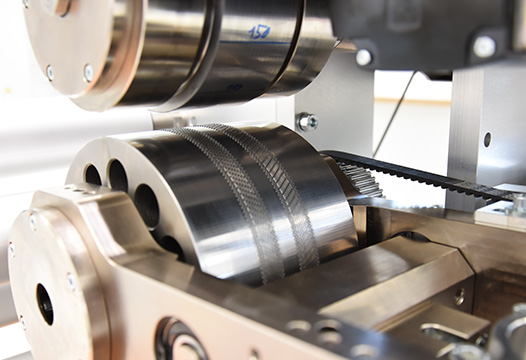

In April Binder together with MS Ultrasonic launched a new generation of in-line welding for the personal care industry. This ultrasonic welding solution makes it possible to produce a closure system without adhesives or glues. A particularly soft closure is created, which also reduces production costs and simplifies processing. This sustainable solution is an efficient alternative to conventional gluing methods and optimises both wearing comfort and cost-efficiency.

Since the initial launch Binder and MS Ultrasonic have been working in partnership to bring this innovation to the market and providing dedicated on-site support to our customers.

This week the Binder personal care team consisting of colleagues from sales, application engineering and innovation spent a day at the MS Ultrasonic Competence Center in Ettlingen, Germany for a cross-training event. Our highly trained participants received additional in-depth training on the implementation of our new ultrasonic welding technology and were able to gain even more advanced and practical knowledge. Both parties also gained valuable insights by learning from each other’s expertise. We focused on addressing initial feedback from the market to ensure that we can address questions effectively, guide improvements and bring speed to the customer’s commercialisation processes.

We focused on addressing initial feedback from the market to ensure that we can address questions effectively, guide improvements and bring speed to the customer’s commercialisation processes.

At the joint workshop our experts also gave short interviews on market feedback and what is coming next. The interviews as well as commonly asked questions will be shared on our LinkedIn accounts in the upcoming weeks. Make sure to follow our account so you don’t miss out!