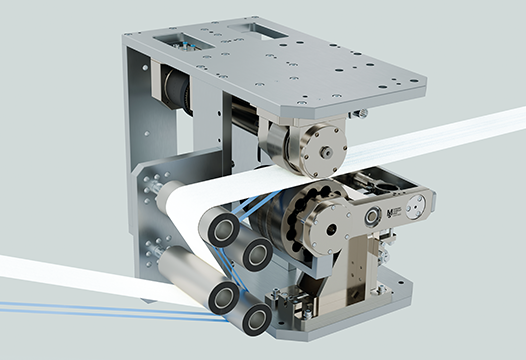

Adhesive-free attachment of our hook fasteners for closure systems

A new generation of in-line welding

This week we launched our new generation of in-line welding at the IDEA trade fair in Miami. Binder and MS Ultrasonic have developed a new in-line welding technology that makes it possible to produce a closure system without adhesives or glues.

Thanks to this innovation costs can be reduced in a sustainable way by integrating proven, trusted ultrasonic technology into your production line.

Our new technology eliminates...

- direct costs of glues/adhesives

- cost of modifying fastener tape for

- adhesive compatibility

- costs in stored ‘expired’ products

- complex components

- need for glue clean-up

More efficiency through reduced...

- energy costs

- waste disposal costs

- use of Binder’s fastener

- logistics costs/warehousing

- production losses (unit yield/day)

- risk of glove tears for caregivers

Also head to our technologies page to find out even more about our new generation of in-line welding.